CAPABILITIES

The aerospace industry turns to us for mission critical, high performance aluminum forgings

ALUMINUM

Weber’s Aluminum Capabilities

• Closed die forgings range up to 3,500 sq in. depending on the geometry

• Cold compression stress relieve to tempers T7452, T7352, and T7454, including incremental stress relieve capabilities

• Utilizing highly advanced, digitally-controlled presses, our capabilities range from 1,500 to 60,000 tons

Aluminum Product Types

Structural / Slab / Blocks / Fittings / Frames / Bulkheads / Beams / Disks / Custom Shapes

FEATURED PRODUCTS

Monolithic Window Frame

7050

Contoured in two directions

Stress Relieved

Landing Gear Shock Strut

Alloy 7075

650 lbs

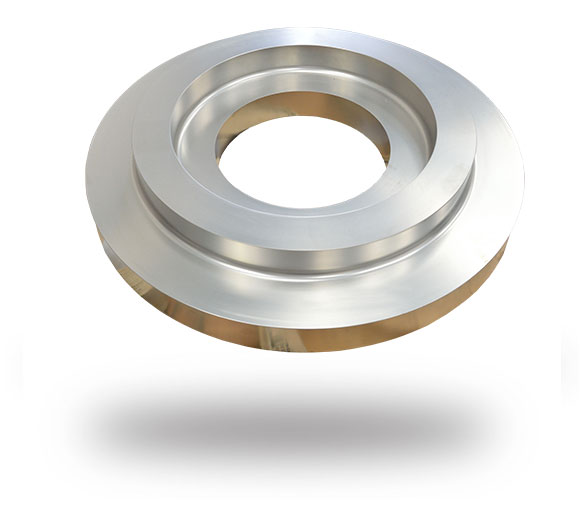

Inboard Wheel

Tempered 2000 and 7000 Series

Transforming titanium ingots into highly-engineering products

TITANIUM

Weber Controls All Aspects of the Process

Our automated, computer-controlled operations reduce variability, shorten lead times and deliver maximum flexibility.

Titanium Product Types

Structural / Slab / Blocks / Fittings / Frames / Bulkheads / Beams / Disks

How We Benefit Our Customers

Low Start-Up Costs

Maximum Flexibility for Change

Reduced Waste

Part Conforming Grain Structure

Increased Throughput

Improved Cycle Time

FEATURED PRODUCTS

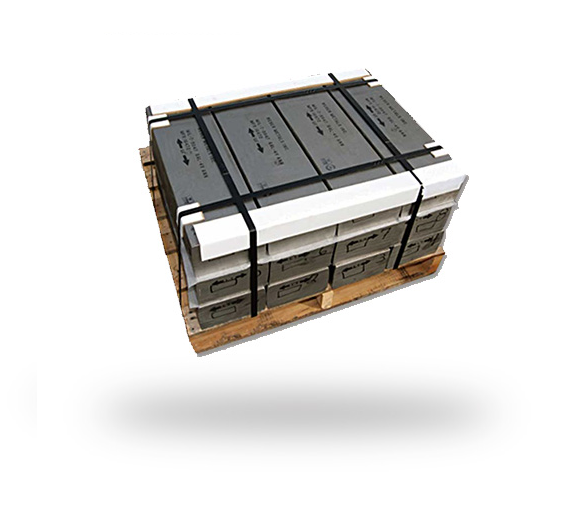

Cut-to-size Hand Forged Blocks

Up to 180” in Length

Cockpit Window Frame

6-4 Beta-Annealed

36” W x 60” L

500 lbs

Shaped and Stepped Forgings

Open-And Closed-Die Solutions

Bulkhead

6-4 Annealed

136” L

500 lbs

Aeroturbine

6-4 and 6-2-4-2 Disks

Manufactured up to 44” Diameter

HIGHly SKILLED & HIGH QUALITY

Our Process

Weber tailors its processes to satisfy customer requirements and is able to manage a large supply base to assist in performing these activities.

Special processing or machining may be incorporated into our process depending on customer needs.

Forging

Various grades of aluminum and titanium alloys

OPEN DIE

Open die forging/forming to create unique preform shapes for closed-die forgings and engineered hand forgings.

- Up to 11,000 lbs

- ST > 4″

- LT > 11″ < 38″

- LG < 22 ft

CLOSED DIE

Closed die forging to create complex forging shapes, concurrently engineered with our customers for ease of manufacture and machinability.

- Up to 4000 lbs

- Aluminum compression stress relieving

- Incremental forging capabilities for large forgings

Weber's stress relieved aluminium close die forgings are shown in their assembled locations for a large business jet cockpit.

ENGINEERED HAND FORGINGS

- Up to 7x less material compared to plate

- Low residual stress in EHF parts

- Multi directional bend capable

- Maximum weight 8,000lbs

LARGE MONOLITHIC FORGINGS

- We have the ability to produce and stress relieve large monolithic forgings reducing final part weight

- Our large presses allow for us to design and replace multiple parts with a single forged piece.

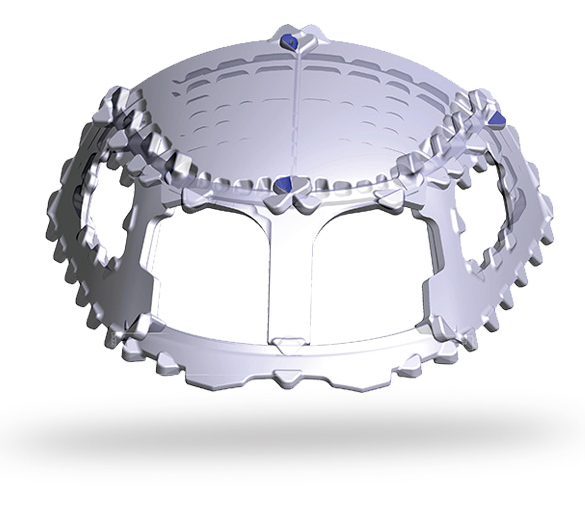

ROTATING PARTS

We currently produce engine disks ranging from 16” – 48” diameter:

- Forge from Ti 6-4. Ti 6–2–4–2, and Inconel 718

- Producing disks weighing up to 1000lbs

- Each disk must have material and physical properties of the highest grade to function in the latest generation of commercial & jet engines

Quality Assurance

Our quality assurance department has full-dimensional inspection capabilities, state-of-the-art coordinate measuring machines, and laser-scanning equipment that map and compare to customer models.

In-House Testing

Our in-house destructive testing facility offers mechanical testing, micro and macro-structural examinations (including grain flow), and chemical composition verification in accordance with the most recent industry and customer specifications.

Non-destructive testing to verify surface and internal material integrity, including:

- State-of-the-art fluorescent penetrant inspection lines for small and large forgings

- Four ultrasonic inspection tanks allowing inspection of open and closed die forgings

Heat Treatment

- Perform low temperature annealing/aging of titanium forgings

- 10,000 lb drop-bottom electric furnace for solution treatment of aluminum

- 50,000 lb gas-fired age furnace for aluminum

- Two 12,000 lb salt bath age furnaces for aluminum

- High-temperature solution treatment and engineered cooling solutions for titanium forgings

Metallurgy

Our Metallurgists participate on various industry committees related to materials and processing such as the Aluminum Association, SAE, MMPDS, FIA & Nadcap.

They are supported by a highly-skilled group of technicians who closely monitor and control forging and heat-treating operations to assure the highest quality product is delivered.

- In-house test material removal / machining

- Macro/microstructural prep / etch / evaluation

- Grain flow evaluation

- In-house wet lab

- Tensile testing

Secondary processing

- Water jet / torch cutting

- Conventional contour cutting

- Hand and large-scale grinding equipment to remove surface burrs and imperfections

The Largest Press in North America

60,000 ton press

The 60,000 Ton press is capable of producing some of the largest monolithic structures in the world. Use of this press reduces piece weight, eliminates the need for more unique part numbers, and optimizes assembly by decreasing the amount of connection points for fasteners.

Ring Rolling

Our Ring Rolling operations are powered by cutting-edge machinery, including:

- SMS Wagner Banning 400/200 -3600/900 CNC Ring Mill: This advanced CNC Ring Mill has 400 tons of Radial and 200 tons of Axial force and represents the pinnacle of precision and efficiency in the industry. It allows us to craft seamless and flawlessly engineered rings to exact specifications, ensuring optimal performance in a variety of applications.

- 300-Ton Vertical Ring Mill: With our 300-ton vertical ring mill, we possess the capacity to handle even the most demanding projects. Its robust design and versatile capabilities make it an essential part of our manufacturing arsenal.

Processing a Spectrum of Alloys

We understand that every application demands unique properties from the materials used. That’s why we offer the expertise to process a wide range of alloys, including:

- Aluminum: Known for its lightweight and corrosion-resistant properties, aluminum is a versatile material with applications spanning aerospace, automotive, and beyond.

- Titanium: Renowned for its exceptional strength-to-weight ratio, titanium is a critical component in aerospace, medical, and military applications.

- Nickel: Nickel alloys exhibit outstanding resistance to heat, corrosion, and wear, making them indispensable in the aerospace, chemical, and oil and gas industries.

- Stainless Steel: Renowned for its durability and corrosion resistance, stainless steel is a staple in countless industrial and commercial applications.

- Super Alloys: We are equipped to work with high-performance superalloys, such as Inconel, Monel, Rene 65, and Hastelloy, prized for their exceptional strength and resistance to extreme conditions.

Custom Solutions

At Weber, our commitment to excellence goes beyond equipment and materials. We understand that each project is unique, and our team of experienced engineers is ready to collaborate closely with you to develop custom solutions that meet your requirements.

Whether you’re seeking precision-crafted rings for aerospace applications, industrial machinery, or any other specialized use, you can be assured of Weber’s quality, precision, and reliability.

Partner with Us

We invite you to partner with us and leverage our Ring Rolling expertise to bring your projects to life. Contact us today to discuss your specific requirements and experience the Weber difference in precision engineering.

Weber’s Large Monolithic Forgings Capabilities

- We have the ability to produce and stress relieve large monolithic forgings reducing final part weight

- Our large presses allow for us to design and replace multiple parts with a single forged piece.

Weber’s Engineered Hand Forging Capabilities

- Up to 7x less material compared to plate

- Low residual stress in EHF parts

- Multi directional bend capable

Maximum weight 8,000lbs